-

Acceleration Mechanical Shock Test Machine

High acceleration impact test bench, impact test system is designed for electronic components, instruments and mechanical products to provide simulated impact environment test equipment, in the process of transportation, use of the product to withstand the impact damage degree basis, can complete half sine wave (basic waveform), post-peak sawtooth wave, trapezoidal wave; Relevant requirements for impact testing of three pulses. SS-10 impact test bench is mainly used for impact test of small and medium-sized products to assess the ability of test products to withstand impact damage. Often used in electronic components, electronic circuit boards and other environmental tests. The test equipment conforms to method 213 mechanical impact test conditions in GJB 360A-96 standard, GB/T2423.5-1995 “Basic Environmental Test Procedures for Electrical and Electronic Products Test Ea: Impact Test Method” and “IEC68-2-27, Test Ea: Impact”; UN38.3 and “MIF-STD202F” specification requirements for impact testing.

-

Walk-in Constant Temperature and Humidity Room

The outer frame structure of this equipment is made of double-sided colour steel heat preservation library board combination, the size of which is ordered according to the customer’s requirements, and is configured according to different requirements. The aging room is mainly composed of box, control system, wind circulation system, heating system, time control system, test load and so on.

-

Flame Atomic Absorption Spectrometer

Model number

KS-8510

Flame Atomic Absorption Spectrometer

Technical programme

1、Advanced factory, leading technology

2、Reliability and applicability

3、Environmental protection and energy saving

4、Humanization and automated system network management

5、Timely and perfect after-sales service system with long-term guarantee.

-

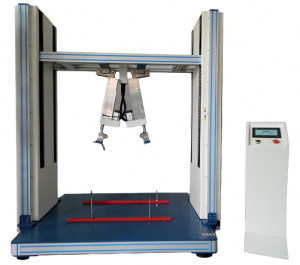

Single Column Digital Display Peel Strength Test Machine for Laboratory Equipment

The machine can be used for a wide range of applications. It can test the tensile strength, elongation, tearing, adhesion, tensile stress, peel, shear, elongation, deformation and adhesion between rubber and metal of various plastic, rubber, electronic or dumbbell-shaped test pieces by changing different fixtures. It is also possible to carry out closed-loop tests for constant stress, constant strain, creep and relaxation, and to carry out tests for torsion and cupping with special equipment.

-

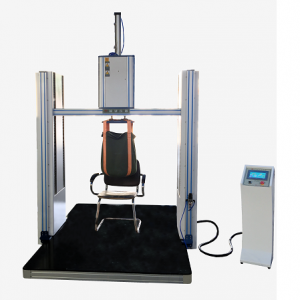

Seat Front Alternating Fatigue Test Machine

This tester tests the fatigue performance of the armrests of chairs and the front corner fatigue of chair seats.

Seat front alternating fatigue testing machine is used to evaluate the durability and fatigue resistance of vehicle seats. In this test, the front portion of the seat is simulated to be alternately loaded to simulate the stress on the front of the seat when the passenger enters and exits the vehicle.

-

Table & Chair Fatigue Test Machine

It simulates the fatigue stress and wear capacity of the seat surface of a chair after it has been subjected to multiple downward vertical impacts during normal daily use. It is used to test and determine whether the chair seat surface can be maintained in normal use after loading or after endurance fatigue testing.

-

Inclined impact test bench

Inclined impact test bench simulates the ability of product packaging to resist impact damage in the actual environment, such as handling, shelf stacking, motor sliding, locomotive loading and unloading, product transport, etc. This machine can also be used as a scientific research institutes, universities, colleges and universities, packaging technology testing centre, packaging materials manufacturers, as well as foreign trade, transport and other departments to carry out the inclined impact of the commonly used test equipment.

Inclined impact test rigs play an important role in the product design and quality control process, helping manufacturers to evaluate and improve the structural design, material selection and stability of their products to ensure safe and reliable operation in a variety of operating environments.

-

Sofa Durability Test Machine

Sofa durability testing machine is used to evaluate the durability and quality of sofa. This testing machine can simulate the various forces and stresses received by the sofa in daily use to detect the durability of its structure and materials.

-

Three-dimensional Measuring Machine

1、Advanced factory, leading technology

2、Reliability and applicability

3、Environmental protection and energy saving

4、Humanization and automated system network management

5、Timely and perfect after-sales service system with long-term guarantee.

-

Anti-yellowing Aging Chamber

Ageing: This machine is used to promote the deterioration of sulphur-added rubber in order to calculate the rate of change in tensile strength and elongation before and after heating. It is generally accepted that one day of testing at 70°C is theoretically equivalent to 6 months of exposure to the atmosphere.

Yellowing Resistance: This machine is simulated in an atmospheric environment, exposed to UV rays of the sun, and changes in appearance are generally considered to be tested at 50°C for 9 hours. Theoretically equivalent to 6 months of exposure to the atmosphere.

Note: Two types of tests can be done. ( Aging and Yellowing Resistance )

-

High Temperature High Pressure Jet Test Machine

The main purpose of this equipment is for vehicles such as buses, buses, lamps, motorbikes and their components. Under the cleaning process conditions of high pressure/steam jet cleaning, the physical and other relevant properties of the product are tested. After the test, the performance of the product is judged to be up to the requirements through calibration, so that the product can be used for design, improvement, calibration and factory inspection.

-

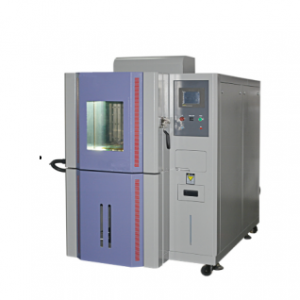

Rapid Humidity and Heat Test Chamber

Rapid Temperature Change Test Chambers are used to determine the suitability of products for storage, transport and use in climatic environments with rapid or slow changes in temperature and humidity.

The test process is based on a cycle of room temperature → low temperature → low temperature dwell → high temperature → high temperature dwell → room temperature. The severity of the temperature cycle test is determined by the high/low temperature range, the dwell time and the number of cycles.

Rapid Temperature Change Chamber is a test equipment used to simulate and test the performance and reliability of materials, electronic components, products, etc. in a rapid temperature change environment. It can rapidly change the temperature in a relatively short period of time to assess the stability, reliability and performance changes of samples at different temperatures.

Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

-

Top